The Buzz on Sandblasting And Painting Near Me

Wiki Article

Facts About Sandblasting Revealed

Table of ContentsAll about Sandblasting At HomeLittle Known Facts About Sandblasting.Sandblasting Adalah Things To Know Before You BuySandblasting Aluminum Things To Know Before You BuySandblasting Adalah - The Facts

Portable applications may or may not recycle the abrasive. A blast cupboard is essentially a closed loop system that permits the operator to blast the part and recycle the unpleasant. It usually contains four parts; the control (cupboard), the unpleasant blowing up system, the unpleasant recycling system and the dirt collection.Automated blast cabinets are likewise utilized to process huge quantities of the same component and also might include numerous blast nozzles as well as a component conveyance system. There are three systems generally used in a blast closet. Two, siphon and pressure, are dry as well as one is wet: A siphon blast system (suction blast system) makes use of the pressed air to develop vacuum in a chamber (called the blast gun).

The abrasive mixture takes a trip via a nozzle that guides the bits towards the surface or workpiece. Silicon carbide and also boron carbide nozzles are much more wear resistant and are frequently made use of with harder abrasives such as aluminium oxide.

Rumored Buzz on Sandblasting At Home

Each application may call for making use of several tools, however, there are a number of essential parts that can be discovered in a normal blast area: A room or control system, generally the room itself, designed to stay covered to avoid blast media from leaving A blowing up system; wheel blasting and also air blasting systems are generally used A blast pot a pressurized container loaded with unpleasant blowing up media A dust collection system which filters the air in the area and also protects against particulate issue from getting away A product recycling or media reclamation system to collect abrasive blasting media so it can be used again; these can be automated mechanical or pneumatically-driven systems installed in the floor of the blast room, or the blast media can be accumulated manually by brushing up or shovelling the material back into the blast pot Extra devices can be included for comfort and boosted usability, such as above cranes for steering the work surface, wall-mounted devices with numerous axes that permit the driver to reach all sides of the work surface, as well as sound-dampening materials used to minimize noise levels.

Mineral: Silica sand can be utilized as a kind of mineral abrasive. It has a tendency to separate swiftly, producing large quantities of dust, exposing the operator to the prospective development of silicosis, an incapacitating lung illness. To counter this danger, silica sand for blowing up is usually covered with resins to regulate the dust.

The Only Guide to Sandblasting Air Compressor

Silica is a common abrasive in countries where it is not outlawed. One more typical mineral abrasive is garnet. Garnet is much more costly browse around here than silica sand, however if used properly, will certainly use equal manufacturing rates his explanation while generating much less dust and also no safety and security dangers from consuming the dirt. Magnesium sulphate, or kieserite, is commonly utilized as a choice to cooking soda.

Many consumers are ready to pay additional for jeans that have the appearance of being used. To provide the materials the ideal worn look sandblasting is used. Sandblasting has the risk of triggering silicosis to the workers, as well as in Turkey, greater than 5,000 workers in the textile industry experience from silicosis, as well as 46 individuals are understood to have passed away from it.

Fascination About Sandblasting Aluminum

A 2015 research confirmed that silicosis is practically inevitable among former sandblasters. Sweden's Fair Profession Facility conducted a study amongst 17 fabric firms that revealed extremely few knew the threats brought on by manually sandblasting denims. A number of firms claimed they would certainly eliminate this method from their very own manufacturing. In 2013, research declared that in China some factories creating worn-look pants are associated with varied non-compliance with wellness as sandblasting cabinet harbor freight well as safety and security laws.Stucco Boy offers sand blasting or poly preparation services as essential actions on re-stuccoing your home. The present problem of your stucco walls are the figuring out aspect of what process is best for you. Both processes include a life time guarantee and create a structurally sound substratum for the leading layer to adhere to. sandblasting and painting near me.

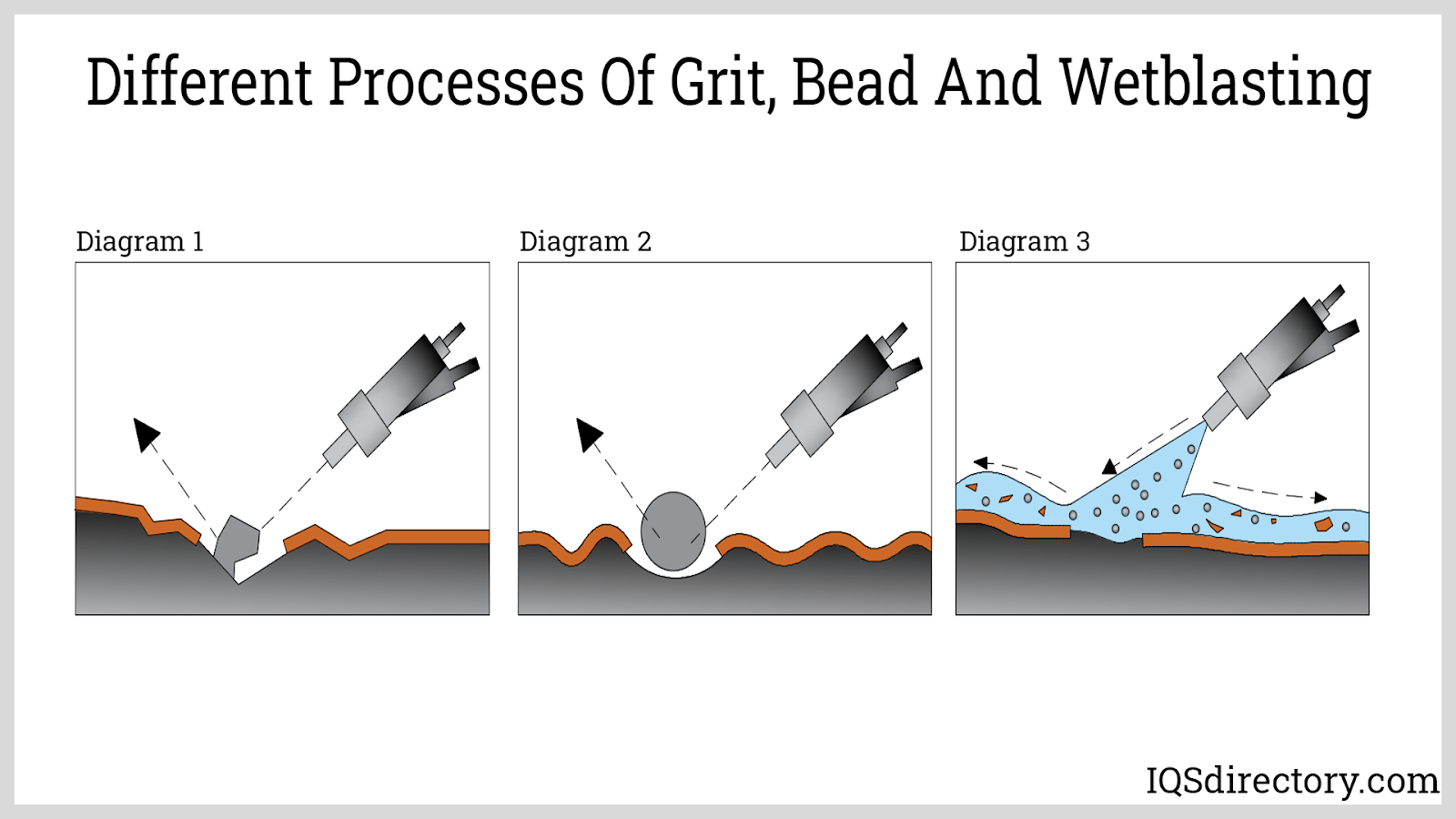

Sandblasting is also recognized as abrasive blasting. Primarily, it is the procedure of forcibly propelling a stream of unpleasant material against a surface area. The sandblasting procedure is done under high stress to smooth a rough surface, roughen a smooth/Shape the surface to remove its contaminants. There are numerous variations of sandblasting process like grain blasting, Soda blowing up as well as fired blowing up.

Not known Incorrect Statements About Sandblasting Air Compressor

If your job profile is related to sandblasting or you owned a company that associated with the exact same process, you need to stay with us. In this short article, we will go over sand blasting makers materials and its pros and also corns. But before it, let me likewise remove a few of the information of its procedure.- This procedure is best matched for metal surface areas, to stop dampness accumulation and prevent water breach in the surface. Sandblasting is the procedure of pushing unpleasant by making use of the pressurized fluid or pressed gas as propellant.

Report this wiki page